Solenoid Valves

JEMKO Valves - Solenoid Valves For Anti-Siphon Control & High Pressure Applications

Providing Superior Solenoid Valves for the Petroleum Equipment Industry for Over 20 Years

JEMKO’s solenoid valves have been used for anti-siphon control on above ground storage tanks in the petroleum equipment industry for over 20 years. JEMKO’s valves are UL listed for hazardous locations and can also be mounted in any position and attitude. JEMKO offers the following valves for anti-siphon control, oil delivery control, and larger bulk plant applications:

- 20 Series Solenoid Valves

- 108 Series Solenoid Valves

- 115 Series Solenoid Valves

JEMKO’s valves are assembled and 100% factory tested prior to leaving the factory, enforcing our goal to exceed our customer's expectations in everything we do.

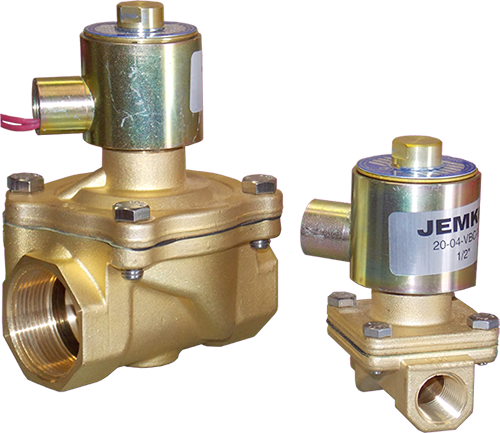

20 Series Solenoid Valves Offer a Better Solution for Anti-Siphon Control

JEMKO’s 20 series solenoid valve is ideal for above the ground storage tanks offering a more economical solution to anti-siphon control. The 20 series is compatible with the number of media such as petroleum products, air, gases, water, and other low viscosity liquids. Some of the main components of JEMKO’s 20 series valves include:

- ½" - 2" NPT

- Normally Closed

- Brass or Stainless

- Viton Seals

- 120vAC, 240vAC, 12vDC, and 24vDC Standard

- Explosion Proof (NEMA7)

The valve offers zero different pressure operations of the ½ - 1½ inch valves, which are ideal for suction pumps. The 2-inch valve requires a 5-psi minimum pressure differential for proper actuation, and it is recommended to be installed downstream from a pump. The 20 series is UL listed for hazardous locations and can also be mounted in any position or attitude; although, installing the valve in a horizontal line with the coil upright will offer the best performance and longest operating life. It is recommended that 100-micron filtration is installed ahead of the valve to increase life expectancy and reduce repairs.

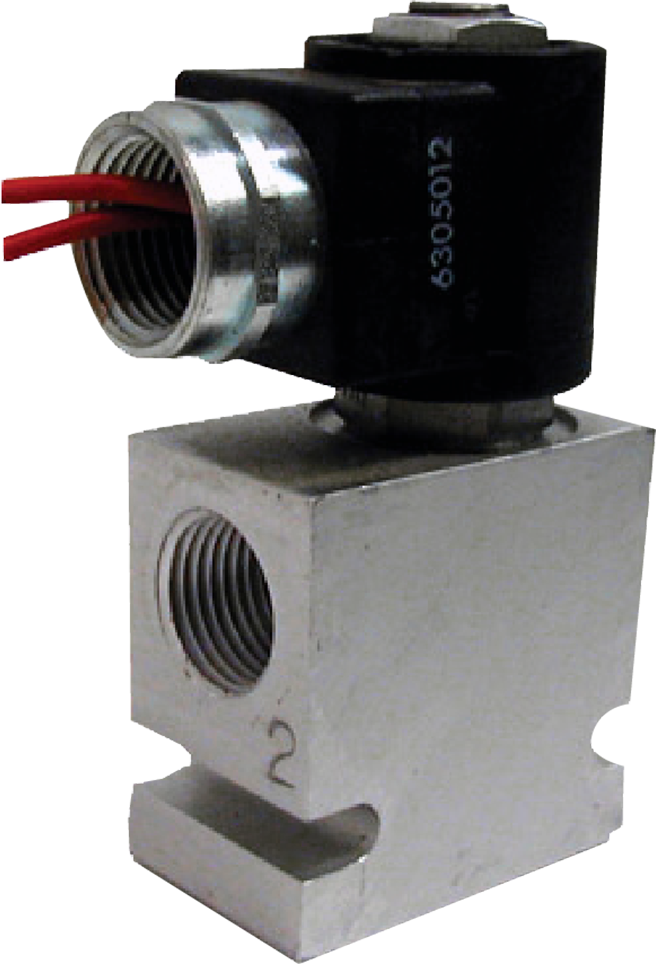

108 Series Solenoid Valves for High Pressured Oil Applications

JEMKO’s 108 series solenoid valves are designed for high-pressure, low flow applications. The 108 series valves are well suited for flow control on oil delivery systems in service garages, auto dealerships, and lube centers. Some of the main components of JEMKO's 108 series solenoid valves include:

- ½" SAE

- Normally closed

- T6 Aluminum

- Buna seals

- 120vAC, 240vAC, 12vDC, and 24vDC Standard

- 3000psi

The 108 valve is compatible with fluid viscosities of 50 to 2000 ssu and operating temperature range from -40°C to 120°C. The 108 valve can have flow rates up to 6-gpm depending upon pressure. The spool valve dimensions are 4”h x 1”w x 2”d. It is recommended that a 25-micron filtration be installed ahead of the valve to increase life expectancy and reduce maintenance.

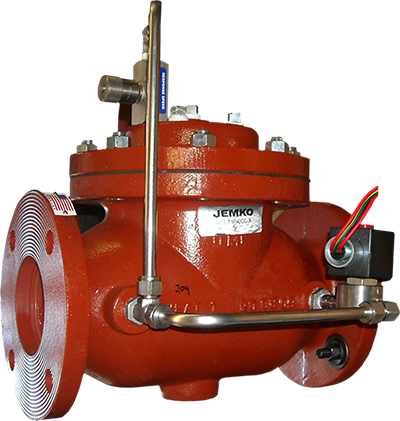

115 Series Solenoid Valves for Various Product Transfer Applications

JEMKO’s 115 series valve is a globe style valve that is ideal for controlling product flow in a desired direction, such as anti-siphon, overfill protection, or other various product transfer applications. These ductile iron bodied valves are designed for heavy duty, high flow, pressure applications. Some of the main components of JEMKO’s 115 series solenoid valves include:

- 3” & 4” Flanged

- Normally closed

- Epoxy coated ductile iron

- 120vAC, 240vAC, 12vDC, and 24vDC Standard

- 5-psi min differential

All OCV main valves are epoxy coated inside and out. The coating is standard on all carbon steel and ductile iron main valves. The epoxy coating is non-porous designed for maximum corrosion resistance. It also helps improve the flow coefficient of the valve. For maximum efficiency, the valves should be mounted in a horizontal line with the coil in the upward position. Other positions are possible, but they may reduce the valves performance or life expectancy.